PCBs are essential components in the various electronic systems that power advanced driver assistance systems (ADAS). Here we will look at the evolution of ADAS, exactly what assistance they provide, and how important the inclusion of reliable PCBs are to their functionality and future.

The evolution of ADAS

As high as 90% of cars manufactured since 2018 will have some sort of modern ADAS fitted. Luxury cars, commercial lorries and other work vehicles were originally the most likely to be fitted with ADAS, but now it is becoming much more commonplace among everyday vehicles. Not only is ADAS becoming more common, but there are also ADAS features that can be integrated into a car after manufacturing, making these products even more accessible.

Far from a new concept, the earliest ADAS was the anti-lock braking system, first used in 1970. Since then more and more ADAS have been developed, including adaptive cruise control, blind spot information systems, and even driver drowsiness detection. Many of these newer features rely on advanced electronic systems, which in turn rely on quality PCBs.

Understanding ADAS and its components

ADAS systems primarily revolve around increasing the safety of drivers, passengers, and other road users. Here are some examples of modern ADAS.

- Pedestrian detection – as the name suggests, this ADAS uses sensors to identify human movement in front of the vehicle, and can even apply the brakes if the situation threatens to become dangerous and the driver hasn’t responded.

- Driver monitoring – this ADAS measures the alertness and attentiveness of drivers through sensors such as eye-tracking and infrared. Again, it may react to obstacles on the driver’s behalf if no evasive action is taken.

- Lane departure warning – can alert a driver to the fact that they have drifted into another lane without indicating – perhaps by accident, or due to tiredness. Cameras are used to monitor markings on the road and track movement.

ADAS are graded in levels that define the amount of automation involved in their system. For example anything considered to be Level 0 might only involve a display, such as a rear-view camera or parking sensors. At the other end of the scale, Level 5 would involve the vehicle ‘making decisions’ autonomously e.g. steering for the driver.

The role of PCBs in ADAS

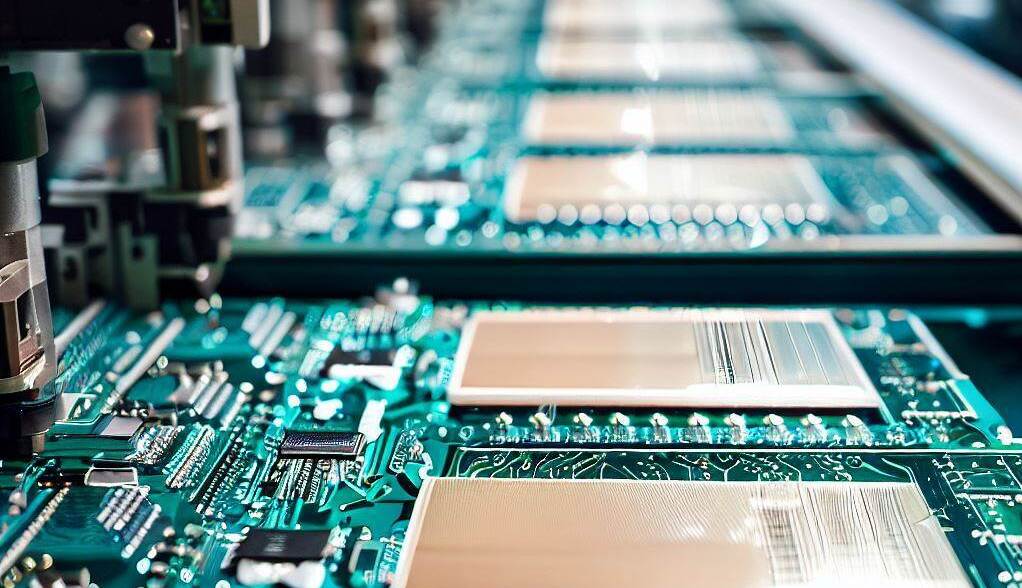

Similarly to the majority of electronics across a wide range of industries, ADAS wouldn’t be able to function without PCBs. PCBs provide a platform for all of the components that make up these systems to be organised and integrated into a compact format. Anything taking up space in a vehicle needs to be lightweight and take up minimal space while still being durable – and well-designed PCBs can easily be all three.

Processors and sensors

For example, PCBs are a fundamental component of Lidar sensors. These sensors emit laser waves – when these waves bounce off of objects in the surrounding environment, the time it takes the light to return back to the car is used to figure out how far away it is. PCBs include components that convert the analogue data from the detectors to the digital data the drivers receive.

PCBs also house the microcontrollers and processors necessary for adaptive cruise control, or emergency braking systems. Obviously, these ADAS can have serious repercussions for the car, driver, and other road users were they to malfunction in any way. The performance and reliability of the PCBs in these systems is paramount to user safety.

The future of ADAS

ADAS features are common among modern cars, but technology is constantly evolving, and there are new ADAS developments on the horizon. The foundations are being laid for improvements in autonomous driving, and self-driving cars are no longer confined to an imagined, sci-fi-inspired future. Sensor fusion (using multiple sensors in a single ADAS to provide multiple sources of data) will make mapping the world around your vehicle much easier, and as a result will be able to detect possible dangers faster and faster.

The use of ADAS is already reducing injuries and insurance claims on the road, and the goal for the future is to make those numbers even lower.

Challenges and opportunities in the ADAS market

As the range that ADAS can cover expands, a challenge arises in the sheer amount of simultaneous computing we may be asking our cars to do. As with most industries, AI is a source of inspiration – but, in the case of the demands on car computing systems, is also a source of problems.

While there are lots of applications for AI in the development of ADAS, AI is particularly computationally intensive. For autonomous driving – a situation where lots of data must be processed and tasks completed in a parallel way – developers need to ensure that algorithms are optimised to allow AI to be a boost for and not a drain on computing power.

PCB designers’ role in advancing ADAS

The PCBs used in ADAS must be able to keep up with the demanding environment in which they are used, and the plans for the future of these vital systems. From facilitating communication between different sensors to managing seamless power distribution, PCBs keep ADAS running – and PCB designers are constantly finding ways to improve upon them.

As previously mentioned, there are many ADAS features that can now be integrated long after the car is manufactured – PCBs must also be able to be integrated at a later date, and this can call for customisable, fully bespoke PCB services.

Ensuring safety and security in ADAS

It is easy to see why these ADAS systems are often found in vehicles such as commercial lorries, where drivers might be on the road for up to nine hours a day, and susceptible to fatigue. The more time spent on the road means higher chances of being involved in some kind of road traffic accident, through your own fault or someone else’s. When it comes to safety, ADAS both prevent and present problems.

The accuracy of these potentially life-saving systems relies on ADAS calibration. ADAS are not able to recalibrate themselves, so after any situation that has the potential to move or damage the various sensors or cameras (e.g. airbag deployment or bodywork) they must be professionally recalibrated.

There is also concern over the need for standardisation across ADAS features, such as the way they are shown on dashboards, and what is included in cars as default. This is to avoid accidents occurring from drivers falsely believing that an ADAS feature is universal when it is not, and getting into an accident as a result. There are also issues regarding liability when an accident occurs as the result of an ADAS malfunction, and ethical concerns over the use of cameras and biometrics.

These are all important factors to keep in mind as ADAS development keeps moving forward.

ADAS: The road ahead

ADAS can only advance as fast and as far as it hopes to with the help of the right PCBs. With decades of experience and accolades to match, we feel qualified to speak on the importance of fast, reliable, flexible manufacturing. Get a free trial or a quote today and enhance your product with ABL Circuits.