Blog

Welcome to the ABL Circuits blog, a bespoke content hub for OEMs, and wider manufacturing professionals. We discuss PCBs, advanced manufacturing methods, and the latest industry news. If our content resonates with you, don’t hesitate to get in touch for a fast and free quote!

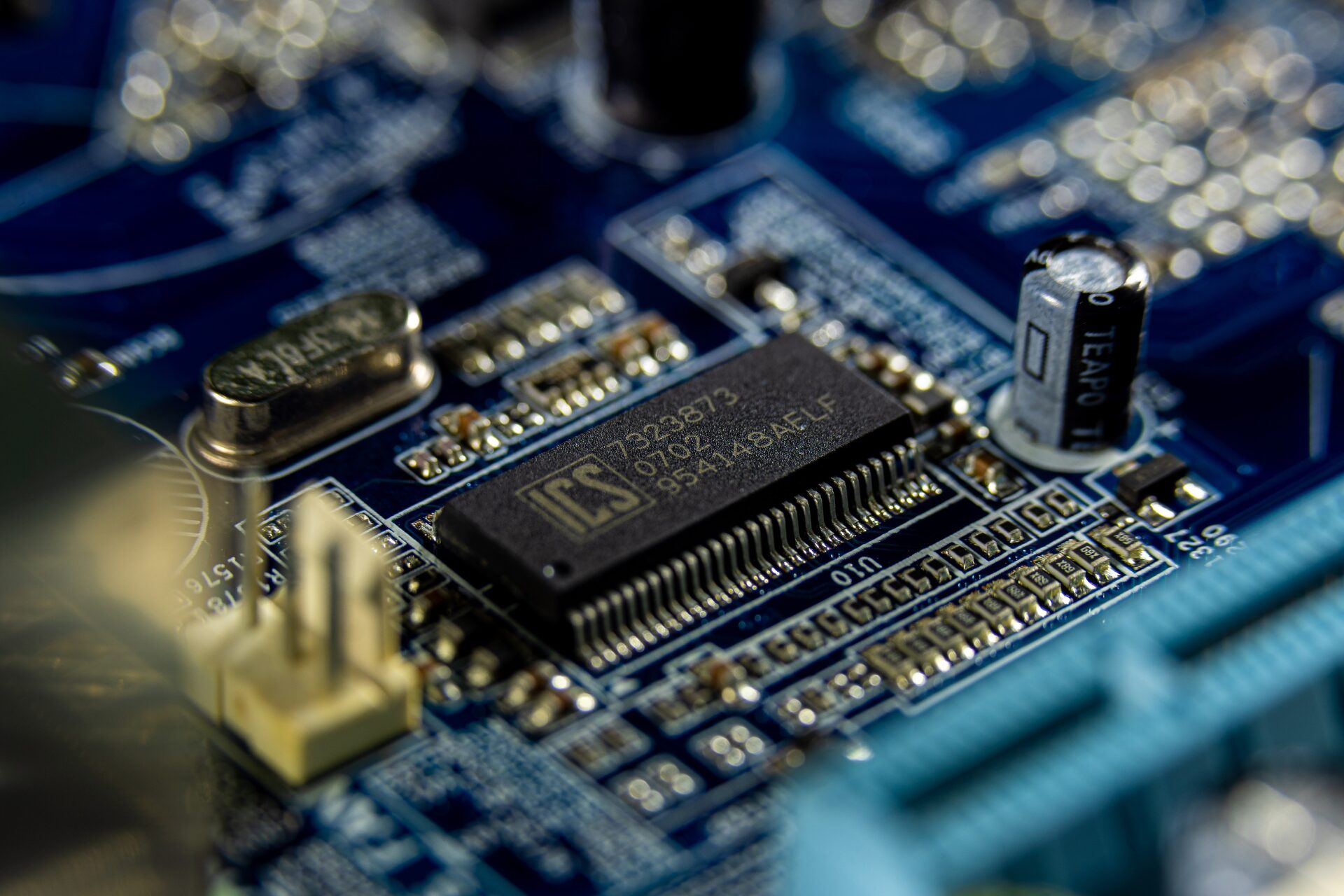

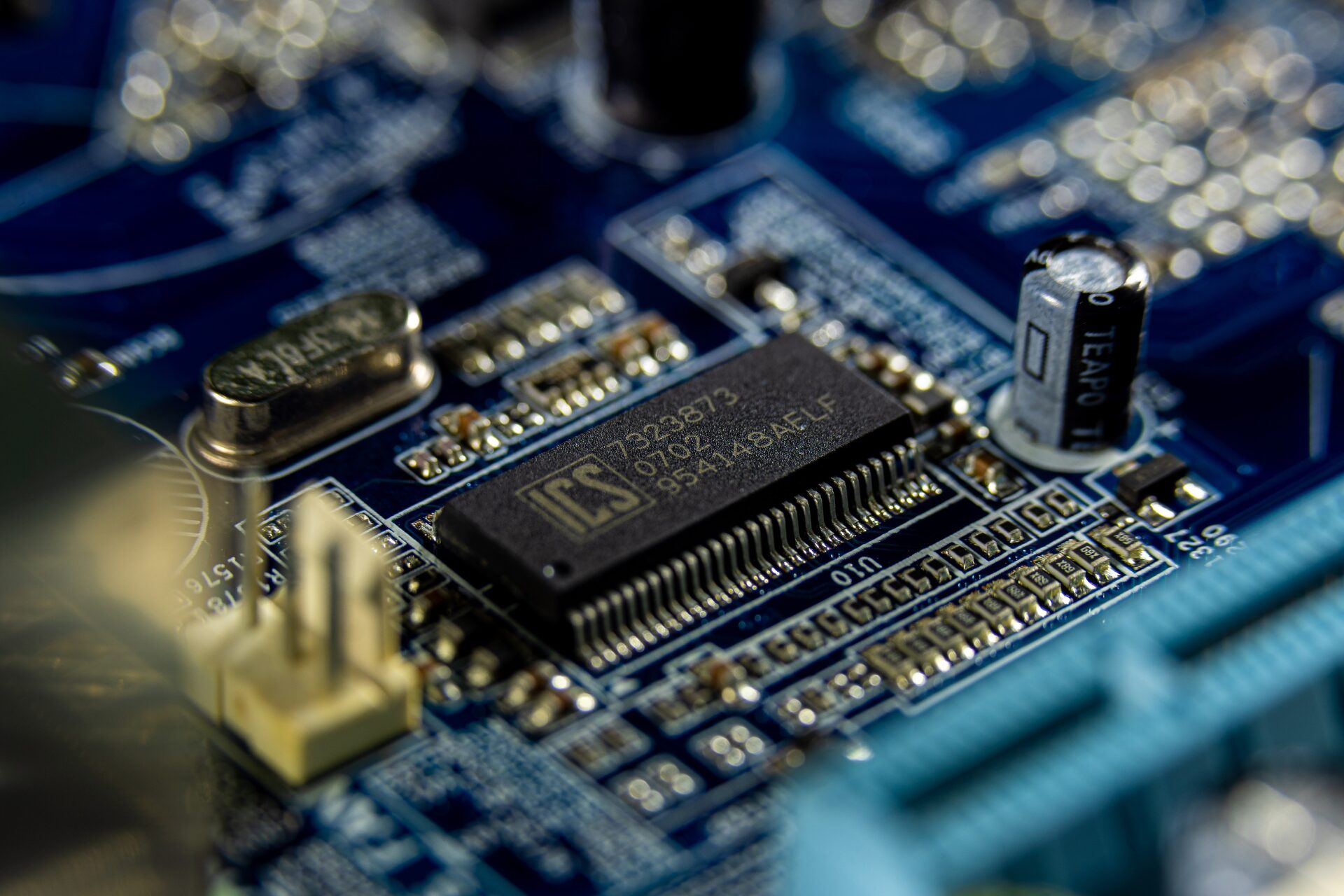

PCBs in the Internet of Things (IoT): Enabling Smart Manufacturing and Industry 4.0

The Internet of Things, otherwise known as IoT, refers to a network of interconnected electronic devices that exchange and communicate data with each other over the internet without human intervention. From household appliances to infrastructure components, every IOT device must meet one key requirement – connectivity. Printed circuit boards (PCBs) can be seen as the […]

Featured Posts

The Role of Flexible PCBs in the Design of Next-Generation Robotics

The robotics industry is dynamic and progresses quickly. It requires advanced technologies to develop next-generation, innovative systems. Flexible printed circuit boards (PCBs) play a vital…

How OEMs benefit from green manufacturing practices in PCB production

The robotics industry is dynamic and progresses quickly. It requires advanced technologies to develop next-generation, innovative systems. Flexible printed circuit boards (PCBs) play a vital…

Satellite Technology: PCBs in Space Exploration and Communications

The robotics industry is dynamic and progresses quickly. It requires advanced technologies to develop next-generation, innovative systems. Flexible printed circuit boards (PCBs) play a vital…

The Role of PCBs in Advanced Driver Assistance Systems (ADAS)

The robotics industry is dynamic and progresses quickly. It requires advanced technologies to develop next-generation, innovative systems. Flexible printed circuit boards (PCBs) play a vital…

The Role of Flexible PCBs in the Design of Next-Generation Robotics

The robotics industry is dynamic and progresses quickly. It requires advanced technologies to develop next-generation, innovative systems. Flexible printed circuit…

PCBs in the Internet of Things (IoT): Enabling Smart Manufacturing and Industry 4.0

The Internet of Things, otherwise known as IoT, refers to a network of interconnected electronic devices that exchange and communicate…

ABL Circuits: championing “Made in Britain” quality in PCB manufacturing

Buying printed circuit boards (PCBs) designed and produced by overseas manufacturers of course has its advantages – cost being the…