Rigid PCBs

What is a Rigid PCB?

A rigid circuit board is the most traditional form of board in the PCB world. They remain hugely popular today and are used in many products consumers use daily.

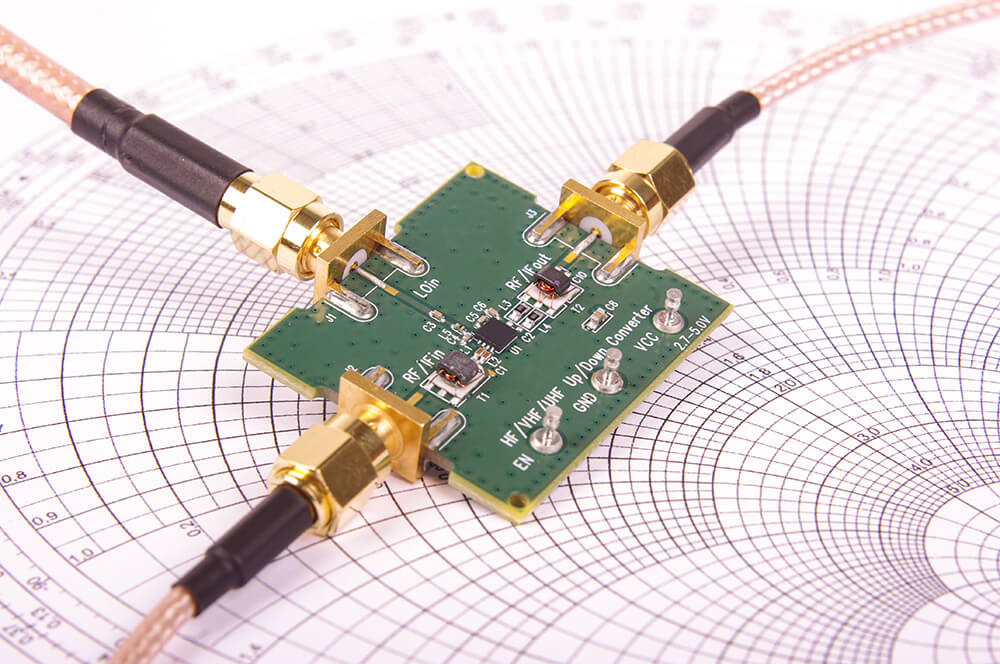

Rigid PCBs are a form of circuit board which are solid and inflexible in their structure and therefore cannot be bent or flexed. They’re made up of several different layers, such as a substrate layer, a copper layer, a solder mask layer and a silk screen layer, which are joined together via adhesive and heat.

Whilst some circuit boards are only single sided, double sided or multilayered, rigid PCBs can take any of these forms depending on the requirements needed. However, once they have been manufactured they cannot be modified or changed.

When should you use a rigid PCB & what are the benefits?

If you are looking for an option that is cost-effective and can be produced in large quantities, then rigid PCBs are a good option for you. They also tend to be more durable than other boards like flexible PCBs, for example, so if you are looking for a hard-wearing circuit board a rigid PCB – with its increased circuit density – is a perfect choice.

Rigid boards are particularly popular in products and industries where it is vital that components remain fixed, as they can cope with both heat and high levels of stress during their lifespan.

Where are rigid PCBs used?

Rigid PCBs are used in many day-to-day products that we rely on for work and communication, such as:

- GPS equipment

- Computers, laptops, tablets and mobile phones

Additionally, they’re used in important medical equipment where they are mainly used in large, non-portable apparatus such as:

- X-rays

- Heart monitors

- CAT scans

- MRI systems

PCBs can withstand high temperatures thanks to their copper and aluminium substrates, which means they are also the perfect boards for the aerospace industry, where they’re used in a variety of essential equipment:

- Aeroplane cockpit instrumentation

- Temperature sensors

- Control tower instrumentation

Get in touch to discuss your PCB requirements

Here at ABL Circuits our PCB services can cater for all of your needs, from rigid PCBs to HDI PCBs and PCB prototypes. If you’re not sure of the right PCB for your product, get in touch with one of our team and we’ll be happy to point you in the right direction, and provide you with a quote if required.

Our reputation as one of the country’s most reliable and trustworthy blank PCB manufacturers has been built up through decades of dedication to our customers and the promise that your circuit boards will be delivered “on time, every time”. Whether you are ordering our bare boards or choosing our total PCB solution, we pride ourselves on offering some of the best lead times in the industry, without compromising our quality and service.

Take a look at our online quotation page and see just how competitive our prices are for your blank PCB service needs.

PCB Manufacturing Services

GET YOUR PCB QUOTE

Fast

You will benefit from the fastest leadtimes in the UK. Your ABL Circuits PCB’s will be delivered within 5 working days as standard.

Friendly

Your order will be dealt with promptly by a friendly and conscientious team, committed to providing a high level of service.

Exceptional

You will also benefit from our exceptional 8 hour same day express service for your urgent prototypes.

Experienced

The knowledge gained from 40 years of experience eliminates your risk in dealing with ABL Circuits.

Dependable

Your deadlines are critical to you and us, that’s why we guarantee you will receive your boards on time, every time in perfect condition.