Multi-layer PCBs

What’s the definition of a multilayer PCB?

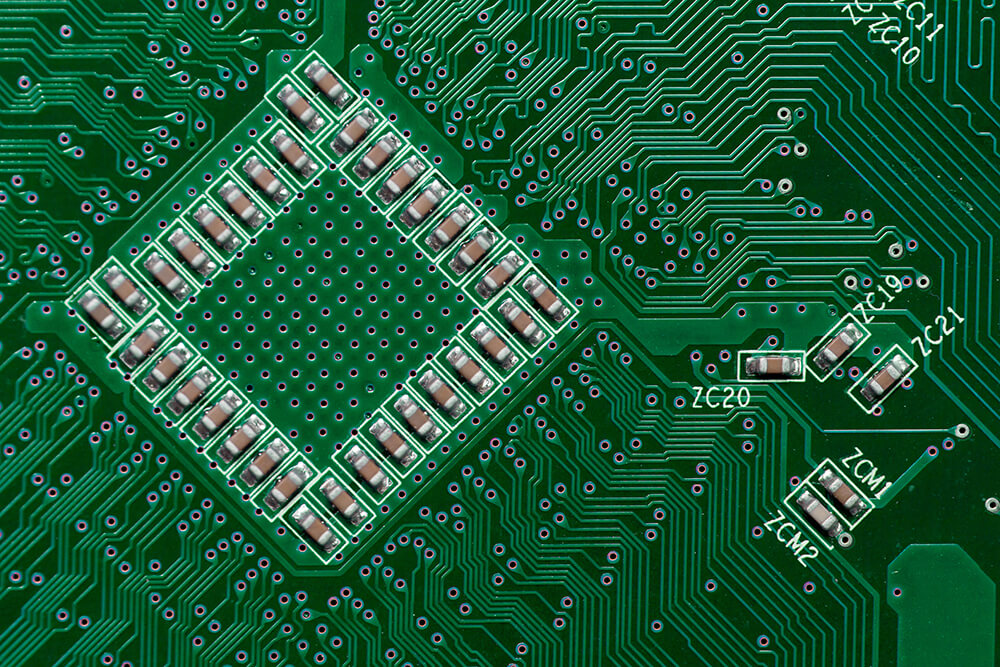

Many printed circuit boards have one or two conductive layers, being built on either a double-sided or a single-sided substrate. A multi-layer PCB is designed and manufactured using several layers of base material. Generally speaking, any board featuring at least three conductive layers is included in this category.

Multilayer PCBs are constructed using a ‘sandwich’ model, featuring numerous double-sided conductive layers separated by a corresponding number of insulating material sheets. These must all be bonded and laminated together under high pressures and temperatures, such that no air gaps remain and the final PCB assembly is sufficiently robust.

Are multilayer PCBs better than double-sided?

The answer here depends on the finished board’s intended application. While multi-layer designs are more expensive to produce, there are numerous scenarios in which they’re beneficial or essential. This is often because they allow for more complex circuits in a smaller footprint. Key advantages of multi-layer PCBs may include:

- Improved durability – more layers stacked together makes for a more robust physical design

- Overall quality – they’re inherently more complex to design and assemble, meaning the production process is often more meticulous

- Better for more complex or high-power circuit designs – speed and capacity requirements for some performance devices may demand a multilayered PCB design

- Space-saving – stacking conductive layers allows for reduced footprint, with larger circuits fitting on a smaller and more lightweight board

- Single connection point – multiple separate PCBs would each need to be powered individually; a muti-layer design usually has just one such input

How are they manufactured and assembled?

You can see a more comprehensive breakdown of exactly how a standard PCB is constructed in our guide to the PCB manufacturing process. As well as a detailed workflow infographic, this page includes a series of our own in-house videos showing precisely how each phase is carried out.

Production of a multi-layer PCB follows much the same core process. However, the manufacturing stage will include additional steps for physically assembling and laminating the more complex substrate that supports the circuitry and components.

What are multi-layer PCBs used for?

ABL Circuits are established industry experts in the design and manufacture of multi-layer PCBs. These typically offer increased functionality for computers and laptops, mobile phones and tablets, medical equipment, GPS trackers, and many other more complex circuits and devices.

ABL Circuits: Almost 40 years of expertise in total PCB solutions

Here at ABL Circuits, we bring over three decades of hands-on technical experience to all aspects of the PCB design, prototyping, assembly and batch manufacturing process. We frequently work with a roster of leading international brands under strict NDA conditions, delivering precision results to full client specifications with some of the shortest lead times in the UK.

You can always rely on our full suite of services for complete end-to-end delivery on your next PCB project. Alternatively, we’re equally happy to be brought in for one part (or several stages) of the design, prototyping, manufacture and assembly process.

Moreover, we’re proud to back up our highly competitive pricing with our unique satisfaction guarantee. As our established industry reputation attests, we’ll get the job done right the first time, every time. Contact us by phone, fax or email to discuss any aspect of a PCB design and production job with a member of our team. Alternatively, you can submit your project outline directly to us for a free quote.

Our reputation as one of the country’s most reliable and trustworthy blank PCB manufacturers has been built up through decades of dedication to our customers and the promise that your circuit boards will be delivered “on time, every time”. Whether you are ordering our bare boards or choosing our total PCB solution, we pride ourselves on offering some of the best lead times in the industry, without compromising our quality and service.

Take a look at our online quotation page and see just how competitive our prices are for your blank PCB service needs.

PCB Manufacturing Services

GET YOUR PCB QUOTE

Fast

You will benefit from the fastest leadtimes in the UK. Your ABL Circuits PCB’s will be delivered within 5 working days as standard.

Friendly

Your order will be dealt with promptly by a friendly and conscientious team, committed to providing a high level of service.

Exceptional

You will also benefit from our exceptional 8 hour same day express service for your urgent prototypes.

Experienced

The knowledge gained from 40 years of experience eliminates your risk in dealing with ABL Circuits.

Dependable

Your deadlines are critical to you and us, that’s why we guarantee you will receive your boards on time, every time in perfect condition.